How do we make PC bottles?

Material we use:

①We recommend using PC materials with fat solubility of 3 ~ 6, if over 6, the material will out of control when injected from die head, like water.

②You can also use 100% recycled material, because of our design of screw, it enables good plasticization.

Steps:

1.Set heating temperature 160,1 hour later,increase them to 220. 1 hour later again,increase them to normal temperature.Don’t forget to preserve heat for 1 hour.That means we need heating for 4 hours at all.

It’s normal temperature during production:

1-258 2-268 3-266 4-262 5-264 6-260 7-250 8-240 9-240 10-240 11-252 12-266

2.Turn on the hopper dryer and heating synchronously.The temperature of hopper dryer should between 100~115℃(dryer should connect water and air).and you should dry the material for 3- 4 hours before production.

Mold temperature controller should be started 1 hour before production.85-105 will be ok.Usually 90.It uses heat transfer oil.And the mold temperature controller needs cooling water.

3.When you start main oil pump,the pump of cooling water must be turned on too.Check the temperature of oil tank,make sure it isn’t over 45℃.

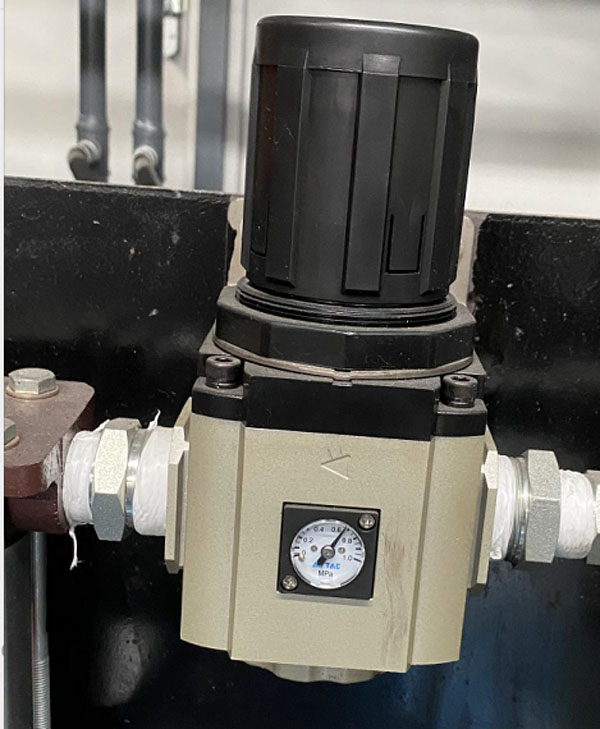

4.When turn on the screw,please make sure water/electricity/gas are all normal(gas pressure 0.8).The first pressurization should be 50,then check whether the screw is turning.The pressure of first shortage don’t over 200.After the storage is full, screw forward and injects,pressurizes slowly:400-600-800.Normally,the pressure of screw won’t over 900,so 850 will be ok.

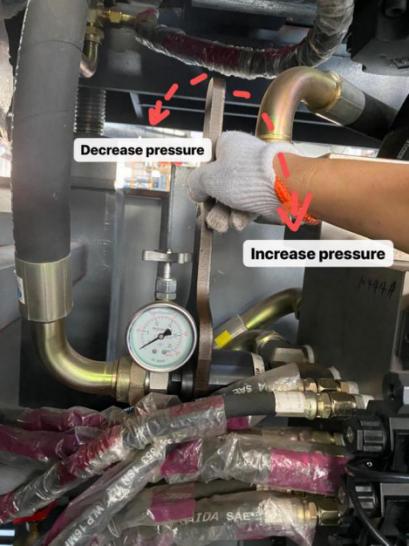

5.Under normal product pressure,the gauge should be at 2~2.5

6.The speed of auto injecting should be controlled within 5s-7s,and the length should be controlled just right.

7.You’d better control the waste material at the mouth of the bottle within 10mm.The shorter the better.

8.Under pressure 857,the gauge should show pressure at 2.

Turn inward by using a special wrench , let the needle of that gauge stay at 2-2.5 while the screw is turning

What kind of PC bottles making machines do you need?

PC bottles Making Machine - TDB-25APC

Electric system: Mitsubishi PLC from Japan and human-machine interface

Hydraulic system: YUKEN hydraulic valves and pump from Japan

Plastisizing system: Effective, energy-saved screw

Die head specially designed for PC material

Clamping unit: Adopting linear slide way with precision up to um grade

Parison injecting: Single hydraulic cylinder without non-synchronization

Mould changing: Extruding cover can be adjusted up and down, diehead can be moved by hydraulic, and mould changing is very easy

| Items | Units | TDB Series |

| Model | TDB-25APC | |

| Specification | ||

| Station | 单 Single | |

| Max. Product volume | L | 25 |

| Dry cycle | pc/h | 600 |

| Output of HDPE | kg/h | 160(PC) |

| Weight of machine | kg | 12000 |

| Size of machine | m,L×W×H | 6.3×2.3×4 |

| Die Head | ||

| Max. Die diameter | mm | 82.5(150) |

| Die Head Heating Zone | 4 | |

| Capacity of Accumulator head | L | 1.9 |

| Die Head Heating power | KW | 9.5 |

| Clamping Unit | ||

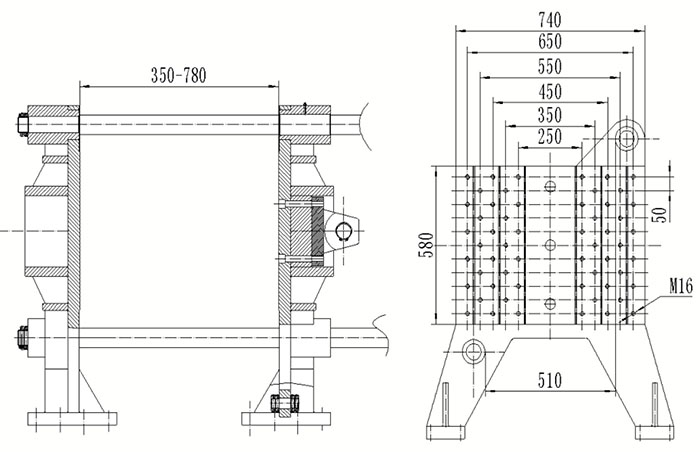

| Platen Distance | mm | 350~780 |

| Clamping force | KN | 215 |

| Extruder Unit | ||

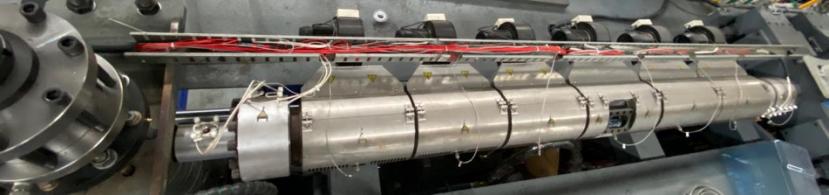

| Screw Diametre | mm | 82 |

| Screw Length/Diametre Ratio | 38(30) | |

| Screw heating power | KW | 40 |

| No.of heating zone(Screw) | 7 | |

| Power Unit | ||

| Oil Pump Motor Power | KW | 45+4 |

| Screw Motor Power | KW | |

| Total Power | KW | 106 |

| Remarks | ||

| Air consumption | m3/min | 1 |

| Blow pressure | Mpa | 0.6 |

| Cooling water pressure | Mpa | 0.3 |

| Water consunption | L/min | 150 |

| Max.Size of Mold | mm,W×H | 550×650 |

How to find a reliable supplier when you are ready to buy machines?

1)Confirm whether the supplier has its own factory or trading company. Generally speaking, suppliers with their own factories are more reliable.

2)Learn the hard power of the factory, including floor area, registered capital, qualification, processing capacity, manufacturing capacity, etc;

3)Learn the soft power of the factory, including company culture, personnel allocation, technical research and development strength, service ability, etc;

4)Ask supplier provide relevant product videos and customer cases for reference.

5)Discuss project details with suppliers in detail and judge whether the supplier is professional through communication.

6)To learn the position and situation of the company in the industry through domestic friends or peer friends;

7)Through the video call, watch the factory live, understand the actual operation.

8)If conditions permit, visit the factory and judge the actual situation and professional level of the factory through field investigation and face-to-face communication.

Zhangjiagang City is one of the important regions for plastic machinery manufacturing in China, especially with strong strength in extrusion blow moulding machines. Here are many large and small manufacturers. When you are ready to buy a blow molding machine to make PC bottles, you may be confused and don’t know how to find a professional and reliable supplier. In the following we would like to share a few tips for you. As you know, a professional and qualified extrusion blow moulding machine has nearly 1000 small parts inside it, and it is difficult for you to be familiar with all parts. It is not necessary for you to know all of them. You just need to pay attention to some important parts of the blow moulding machine as follow:

4.1 Plasticizing system

The most important part for PC bottles making machine is plasticizing system. Unlike other machines, PC bottles making machines don’t have gearbox, extruder motor. Plasticization is carried out through the connection of hydraulic motor and screw.

Screw and barrel: The performance of the screw determines the productivity, plasticization quality, dispersion of additives, melt temperature, power consumption, etc. of an extruder, which directly affects the scope of application and production efficiency of the extruder. Through the rotation of the screw, the plastic can be squeezed so that the plastic can move, pressurize and obtain some heat from friction in the barrel. The plastic is mixed and plasticized during the movement of the barrel, and the viscous fluid is melted. When the body is extruded and flows through the die, it obtains the desired shape and is formed. Like the barrel, the screw is made of high-strength, heat-resistant and corrosion-resistant alloy steel. Our screw diameter for PC bottle making machine is 82mm. The length-to-diameter ratio, is 38:1. When the length-to-diameter ratio is large, the temperature distribution of the material can be improved, which is conducive to the mixing and plasticization of plastics, and can reduce leakage and reverse flow, and improve the production capacity of the extruder. That’s why our PC bottle making machine can even use 100% recycled material to produce.

4.2 Die Head

The die head is the forming part of the extrusion machine, which mainly includes the head, mandrel, die mouth, core model, adjusting screw, etc. The die head is connected with the extruder. The extruder provides a plasticized plastic melt with a certain temperature, pressure, viscosity, and runner speed for the die. After the plastic melt enters the die, the original spiral motion mode is changed to the linear motion mode. The flow and shear process of the melt in the runner makes the plastic melt further uniform. The melt is decompressed in the flow channel to make the speed uniform, and the melt is further compressed and pressurized to generate the necessary molding pressure to make the extruded product compact. Finally, the melt undergoes the forming section of the die to become a parison with a certain cross-sectional shape and size, and the parison is then processed and cooled to form a product.

For plastic extruding die head, you would need to use it several times to know its quality. A good blow molding machine die head has better rheological properties, which can make the plastic melt have a better preform structure, and at the same time, it is easier to change the material and color of the plastic material.

4.3 Mold Opening and Closing System

Different blow moulding machine have different models and series, and different models may have different mold opening and closing devices.

For PC bottles making machine. Mold opening and closing are usually controlled by a combination of linear guide rail and hydraulic valve.

4.4 Control System

Human-machine interface: Human-machine interface control panel screen has such functions as follow: visual display providing the best support to easily set, search, change and store the parameters, the controlling system has self-diagnosis, functions, the malfunctions can be displayed on the screen. Now we usually adopt INOVANCE brand.

4.5 Hydraulic System: All the elements used in hydraulic system are famous brands such as Japan YUKEN, it has advantages as follow: quick response, high energy-efficiency and stable.

Electrics:

These are the brands of electric devices that we use in PC bottles making machine.

| Name | Supplier |

| Microcomputer Control System | MITSUBISHI PLC, Japan |

| Touch Screen | INNOVANCE,CHINA |

| Parison Controller | MOOG ,Japan or AUTOMATA,GERMANY |

| Contactor | SCHNEIDER, France |

| Air Switch | SCHNEIDER, France |

| Motor | SIMENS BEIDE, Germany

|

| Power Resource | MEAN WELL, Taiwan |

| Inverter | INOVANCE |

| Relay | OMRON, Japan |

| Transducer | GERMANJET, Germany OR GEFRAN, Italy |

| Solid state relay | ARICO, Taiwan |

| Servo valve | Rexroth,Germany |

| Servo pump | Sumitomo,Japan |

As you know that plastic extrusion blow molding machines is supposed to work non-stop in your plant, electric parts are very easy to be damaged if the quality is not good. You can find electric parts from international manufacturers in your market, but prices would be much higher than those in the Chinese market. We always recommend opting for our after-sales service, because you can also find counterfeit products in your local market. Anyway, you only need to know what brand they use in their machine when you are visiting plastic extrusion blow molding machines manufacturing factories in China.

What auxiliary machines you need whenenen buying PC bottles making machine.

1.Dryer&Auto-loader

Dryer is used to dry the PC material. Loader feed the material to the hopper. It helps save labor from carrying materials. By blocking the transport system, it improves the workshop environment, reduce pollution and ambient temperature. When choose auto-loader, 400kg/hour is enough.

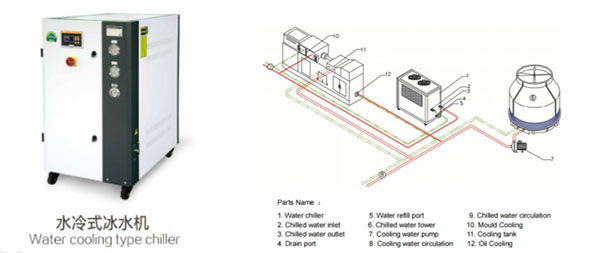

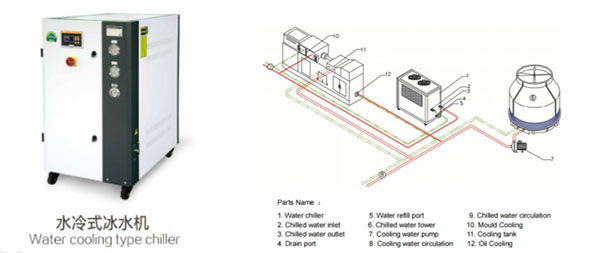

2. Chiller

Cooling water is mostly used to cool the mold. (1) If the mold to hot, it is not easy to molding the products. (2) Facilitate the demold, then the jerry can won’t stick to the mold. (3) Decrease the time high pressure inflate, after that the cycle time can be faster.

3.Mixer

Mixer are used to mix up raw material and color master batch to make the pc bottles have attractive colors. Or it can mix up virgin material and recycled material, helping save cost of materials. Control box sends signal to the motor, and it starts rotating. Motor main shaft drives blades to mix different materials with the rotation, which evenly mix the material in short cycle. When timer of the control box reaches set time, the motor stops. At this time, open the discharge port of the hopper, and discharge the material. Then, the mixing is finished.

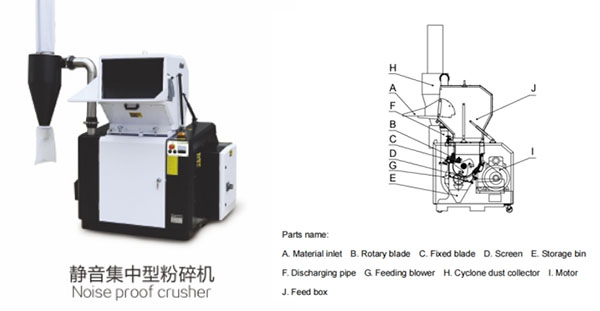

4.Crusher

During processing progress, there will be waste material or some failed pc bottles. Crusher is suitable for granulating plastic material. The waste materials enter the cutting chamber via material inlet (A). The rotary blade (B) and fixed blade (C) granulate the materials. The particle size is controlled by the size of screen (D). The screen (D) is located at the bottom of cutting chamber. Thus it is convenient to replace screen to other different sizes.The granulated materials are dropped into the storage box (E) via the screen and be conveyed via discharging pipe (F). Use feeding blower to absorb the granulated materials into cyclone dust collector to separate the air and dust. The particles can be reused directly or sent to somewhere for storage after being granulated.

Tips: When choose crusher, we recommend to choose crushers with dust separation function. Because dust of recycled material can’t be feed to the machine, otherwise there will be crystal in the finished bottle.

5.Air compressor

We usually supply customers with a set of air compressor which consists of air dryer, filter and air tank. Many functions need compressed air, such as high pressure inflate, deflashing, cutter and so on.

6.Mold temperature controller

Pc bottles have high requirements in temperature. To make pc bottles, the neck and the bottom of the mold should be cooled by cooling water, but the middle of the mold should be heated.

There are still many other auxiliary engines that improve the automation of your company, helps save labor and increase the production efficiency.

What do you need to prepare before getting the PC bottles manufacturing machine?

First of all, you have to conform the area you need for your plant. After the machines arriving at your factory, the first step is to install the legs and adjust the balance of them. Also, you need to tighten all the screws, as the screws may loose during the long-time transport. Besides, the necessary things you need in your factory are water, electricity, gas and hydraulic oil.

6.1 Water

The water source can be a cooling pool pump system, also can be adopted according to the requirement of the finished products. The mold uses cooling water or all the system can also use cooling water from chiller.

If you have several machines, it is better for you to build a water pool to store water in your factory. The function of the water pool is the same as the water tower. Also, you need to connect the water chiller, as the water temperature of the water pool is not low enough to cool the mold.

The functions of the water are as follows:

To cool the mold:During production, the plasticizing system heats the plastic raw materials to the required temperature to melt them, and then injects the melted raw materials into the cavity of the mold. The plastic raw materials are cooled, solidified and shaped in the mold, and then the mold opened, come out products. However, with the continuous feeding and forming, it will not be long before the temperature of the mold will be heated by the high-temperature plastic raw materials to close to the temperature of the raw materials, and the cooling and forming of the high-temperature raw materials will be very slow. If the mold and products are not cooled enough, the products will be deformed. The quality of products can not be guaranteed, which will also affect the efficiency of production. In this regard, people have taken the measures of forced cooling of the mold, adding a cooling water channel to the mold, supplying cooling water, and cooling the mold through the circulating cooling water, so as to carry out continuous production and improve the production efficiency.

To cool the blow pin: If the temperature of the blow pin is too high, the product mouth size will get small.

To cool the screw: If you didn’t connect the water in the material inlet part, the temperature in the front of the screw passes to the back, the material will agglomerate.

To cool the oil tank: There is a water cooler outside the oil tank.

6.2 Electricity

You can refer to the manual to know the total power needed to run the machine. Before you get a quotation from us, we also need to know the voltage and frequency of your country. When removing the electrical box before shipment, we will mark the number on the wires. It will be easier for you to connect all the wires. The grounding place will be better if close to the machine. If not grounded well, starting the machine is strictly prohibited.

6.3 Gas

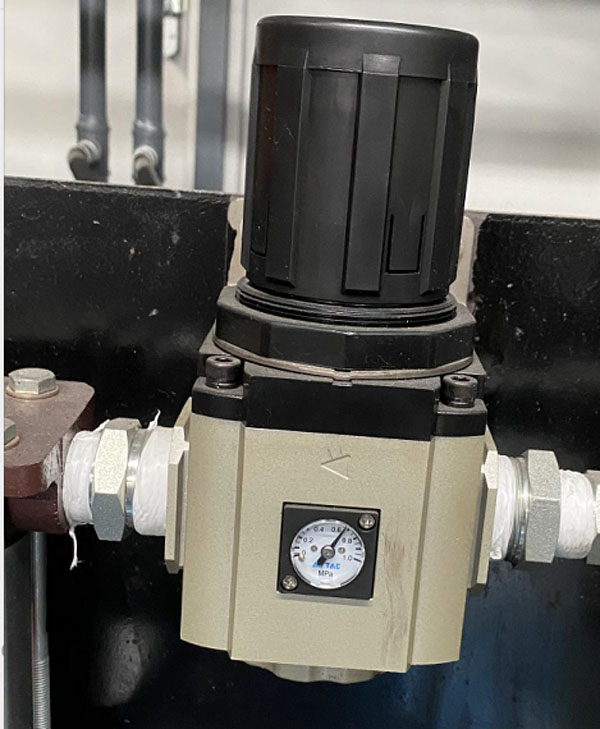

You have to prepare the air tank and air compressor to provide the gas. Make sure the total air source pressure 0.6~0.8 mpa. The pressure reducing valve for high pressure action is 0.6~0.8(such as high pressure inflate), pressure reducing valve for low pressure action is 0.3(such as pre-blowing).

6.4Hydraulic oil

Before operating the new machine, please fill the hydraulic oil into the oil tank.

Open the filter of the oil tank to fill in hydraulic oil N46#. Check the oil level from view window on the side of oil tank. For PC bottles making machine, about 800L.